22

2020Total Manufacturing Cost: Formula, Guide, & How to Calculate

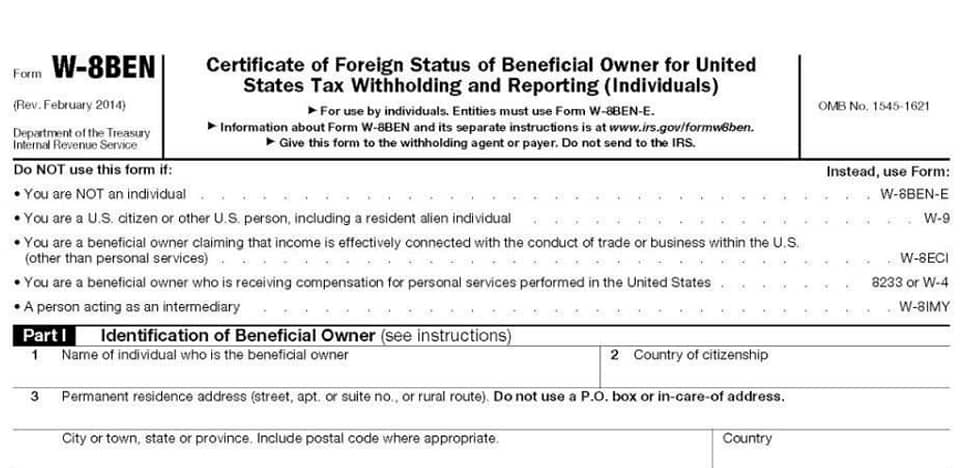

Manufacturing overhead is the final component of the total manufacturing cost formula. Manufacturing overhead (MOH) refers to expenses on external costs, like electricity, rent, insurance, maintenance costs, etc. Once you understand the true cost of your manufacturing, you can more accurately account for inventory on your balance sheet and cost of goods sold on your income statement.

- However, it also informs another critically important KPI, namely, the Cost of Goods Manufactured (COGM), which in turn is necessary to calculate the equally important Cost of Goods Sold (COGS).

- Total manufacturing cost is a financial metric that expresses the total amount of funds spent on all production activities during a financial period.

- Total manufacturing cost, when compared with income and revenue, provides clarity around profitability and overall business performance.

- Adding these three together is how you calculate the total manufacturing cost formula.

- Use our kanban board as a tool to track cost estimates versus actual costs, order management and inventory management alongside production.

- Manufacturing Overhead Cost includes all indirect expenses related to the manufacturing process.

Businesses can use this figure to monitor the percentage of revenue that goes into manufacturing costs. By reducing total manufacturing costs, businesses become more productive. The key difference between direct costs and indirect costs is that direct costs can be tracked to specific item, and tend to be variable. Examples of direct costs include direct labour, materials, wages, commissions, and manufacturing supplies. Both of these figures are used by manufacturers to evaluate the total costs of running their business.

How to calculate manufacturing overhead?

If your machinery suffers breakages or depreciation during this process, you should consider incorporating these financial losses too. Manufacturing overhead also includes the indirect costs that are not part of direct materials or direct labour. Remember that you only need to calculate labor for the production period you’re calculating. Total manufacturing cost is an accounting metric that sums up all of the costs that go into manufacturing a company’s products. These include direct material and labor costs, as well as manufacturing overheads.

It might be difficult to calculate– and it might be difficult to see– but it exists. Rose Burn’s manufacturing overhead is $170,000 ($50,000 manufacturing supervisor gross pay + $60,000 factory rent + $45,000 factory utilities + $5,000 depreciation + $10,000 supplies). Splitting up your manufacturing costs into three buckets helps you see where you’re spending too much and where you should invest more. Total manufacturing cost is an important metric for providing insight into an organization’s financial health, particularly when used with other formulas. Better insights mean you can save on materials, labor, and other resources by identifying areas where improvements can be made.

What are material costs in manufacturing?

John brings over 10 years of career experience across various operational and data analytics roles. As already explained, your costs will fall into one of two categories. This guide covers everything you need to know about employee and employer obligations.

Raw materials go through any number of types of operations in the course of manufacturing, such as welding, cutting, etc. When figuring out direct material costs, it’s important to distinguish between direct and indirect. Indirect costs are subsidiary material costs, such as shop supply costs, perishable tools and equipment costs. Your business’s total manufacturing overhead summarizes the indirect costs of producing finished goods.

Manufacturing Cost vs. Production Cost

This data is also shared with other features, such as our dashboards and reports. Knowing the cost of manufacturing a product is more than being able to calculate the price and profits of the item. It helps manufacturers make more insightful decisions in terms of staying competitive and how production manufacturing can be profitable enough money to remain a viable business. Best of all, by using the information you provide in your bill of materials, Katana automatically calculates the costs of each operation using the moving average cost formula. In addition to profitability, pricing decisions can also impact other strategic objectives, such as market share and customer satisfaction.

- In other words, the direct labor costs that go into the total manufacturing cost calculation are only made up of staff directly involved in the production part of the business.

- In spite of the similarities in the names, the cost of goods manufactured (COGM) is not interchangeable with the cost of goods sold (COGS).

- As for overhead, you pay for regular equipment maintenance and upgrades as well as utilities and insurance for $7,000 per month.

- That’s why you need a reliable partner to buddy up with and slash your costs.

- Examples could include glue, water, cleaning product or any other ingredient that has been used at some point during production.

Additionally, TMC can help uncover inefficiencies in the supply chain, shop floor, and inventory levels. Keep in mind, there are certain roles that don’t have anything to do with direct labor. Support staff such as HR and Accounting don’t directly help create the product. Your total direct manufacturing cost formula direct materials are the actual materials you need to buy, refine, and consume to make your product. In the simplest terms, it’s the total cost to make your products during a period of time. There are also other (very important!) parts of these equations to account for.